A.C. Adjustable Frequency Drive (AFD) Theory:

A.C. squirrel cage induction motors are typically characterized as constant speed when they are run from a 60Hz power source. If the source frequency can be adjusted, the motor speed and associated motor characteristics can be controlled to various levels of performance. Variable speed crane drives use existing A.C. power and convert it to D.C. via an electronic technique known as pulse width modulation (PWM). The Direct Current is then turned back into variable frequency alternating current (VFAC). With variable frequency A.C., the motor is now capable of performing to torque, efficiency or speed characteristics that are not typically associated with standard A.C. systems.

There are huge benefits in increased operating control and reduced maintenance costs by upgrading your crane controls to adjustable frequency drives. When switching to an AFD, conventional control systems such as resistor banks, timers and fluid couplings can be done away with. In addition, contactor arcing is eliminated and brake wear is reduced resulting in longer service life on your crane equipment. In place of these eleminated maintenance items frequency drives provide further reductions in wear through dynamic braking, controlled acceleration and deceleration, and motor over-current and over- temperature protection, which are inherent features of frequency drives.

AFD’s also allow more operating versatility! Their flexibliity in speed selection and slower speeds offer precise load positioning and reduced load swing.

General Advantages of Frequency Drives

McLaughlin Hoist & Crane is proud to provide adjustable frequency drives that have a proven track record for providing unmatched performance and reliability to the overhead material handling industry. Each unit is designed with versatility, reliability, and safety in mind. Models range from more basic, compact low cost units to advanced units featuring exclusive crane and hoist software. The following drives meet the demands of Material Handling applications from 1/4 HP to 1500 HP.

Impulse® G+ Series 4

Impulse® G+ Series 4

Impulse® VG+ Series 4

Impulse® VG+ Series 4

Impulse® G+ Mini

Impulse® G+ Mini

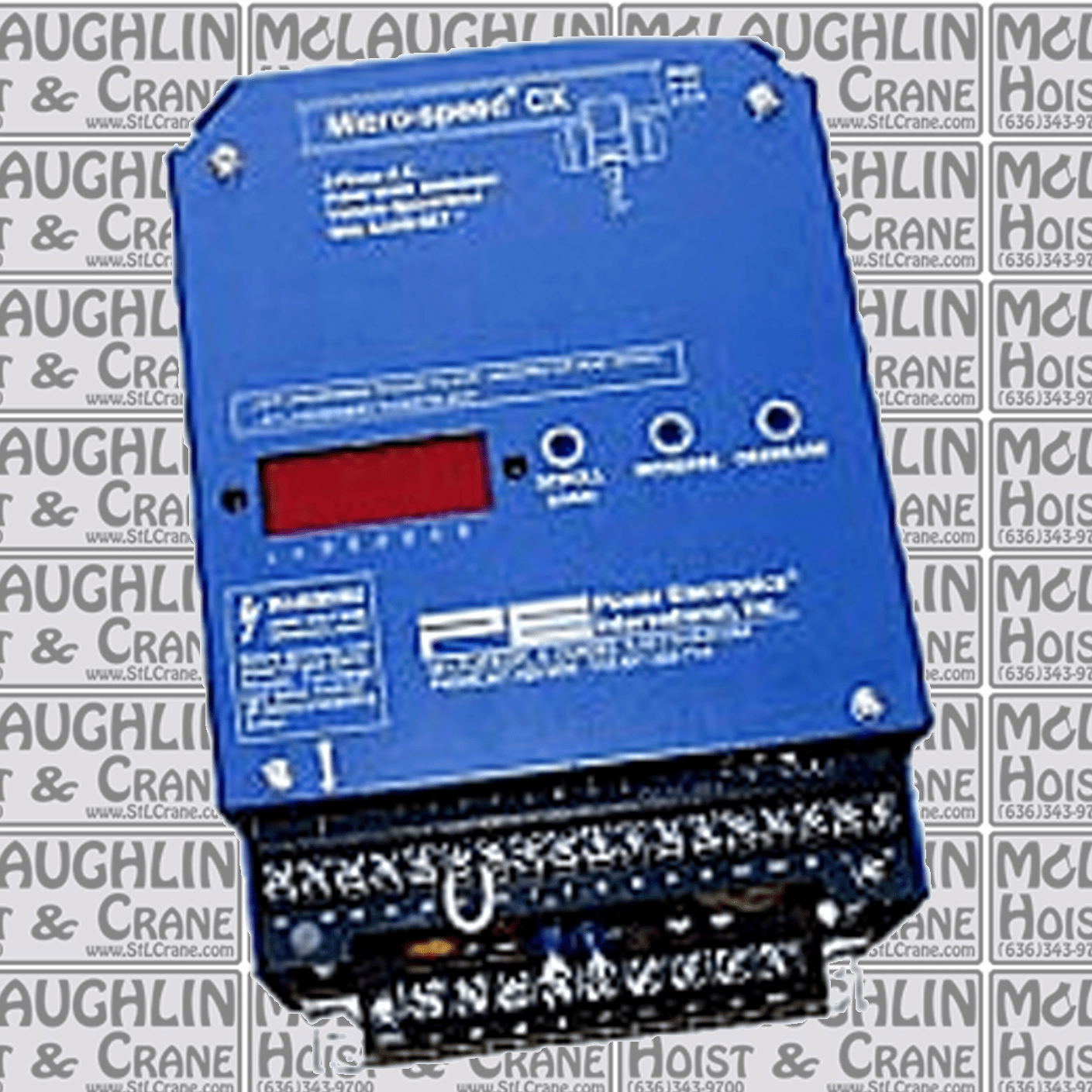

Power Electronics Micro-Speed CX

Power Electronics Micro-Speed CX

Power Electronics Micro-Speed MV

Power Electronics Micro-Speed MV

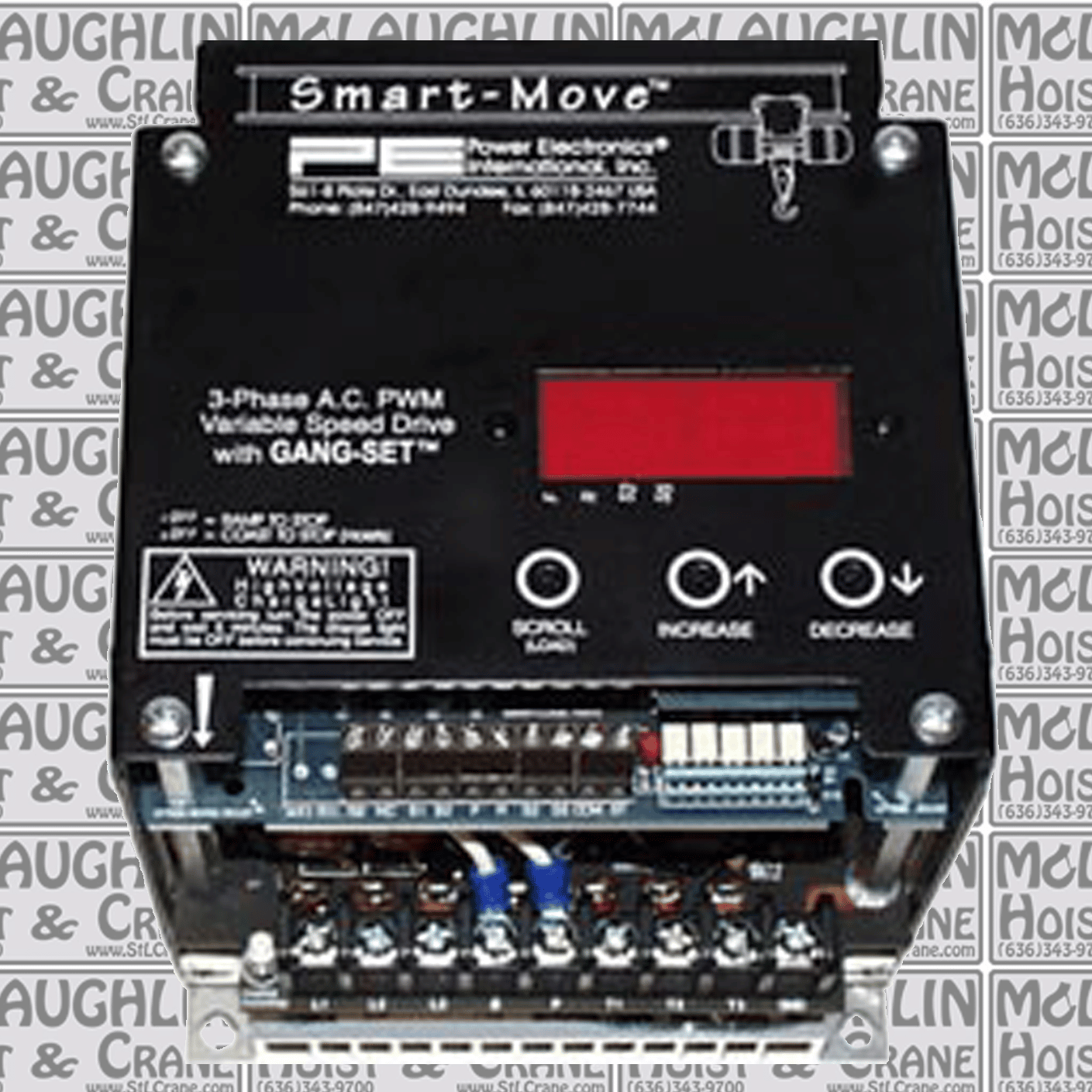

Power Electronics Micro-Speed Smart-Move

Power Electronics Micro-Speed Smart-Move

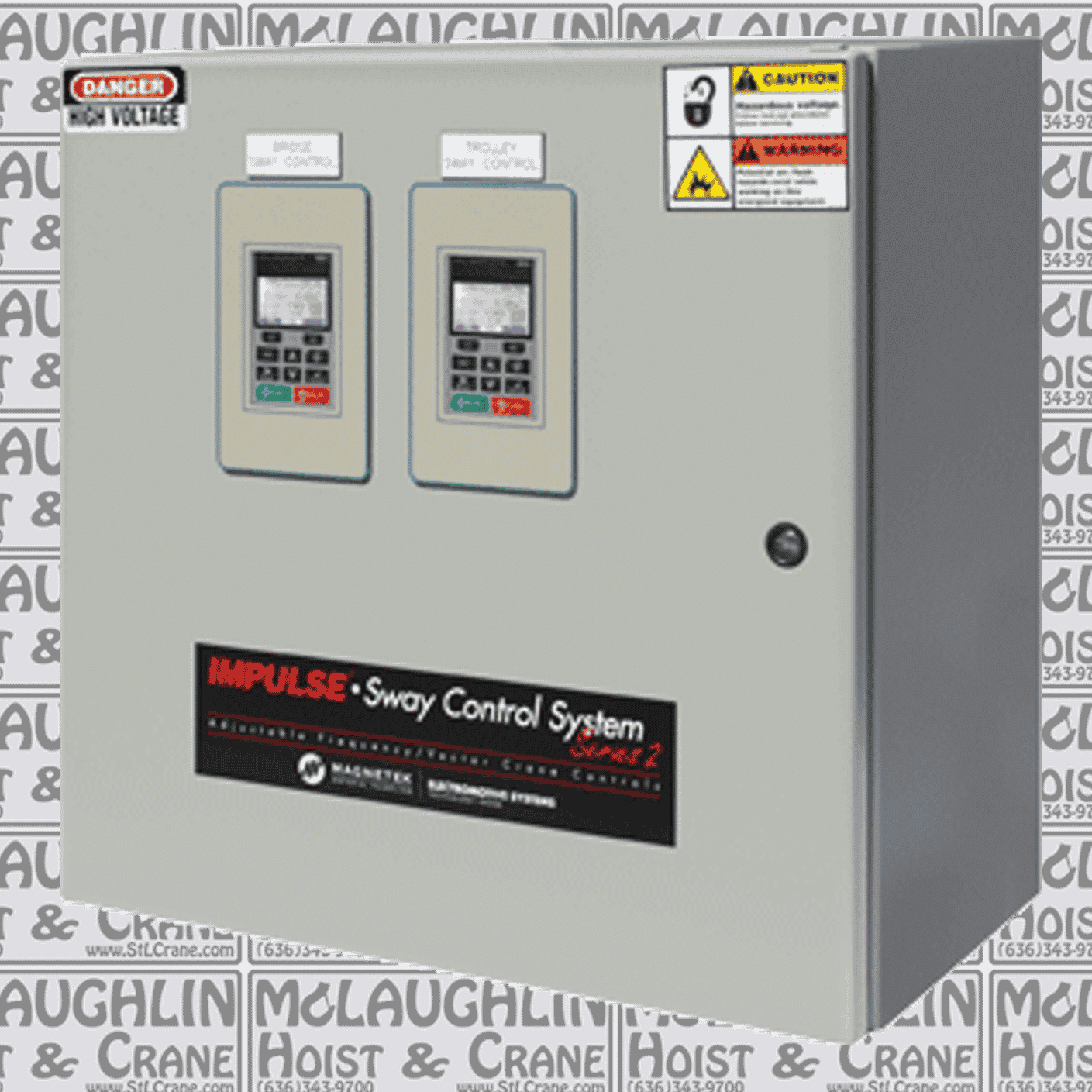

Magnetek Impulse Sway Control System Series 2

Magnetek Impulse Sway Control System Series 2

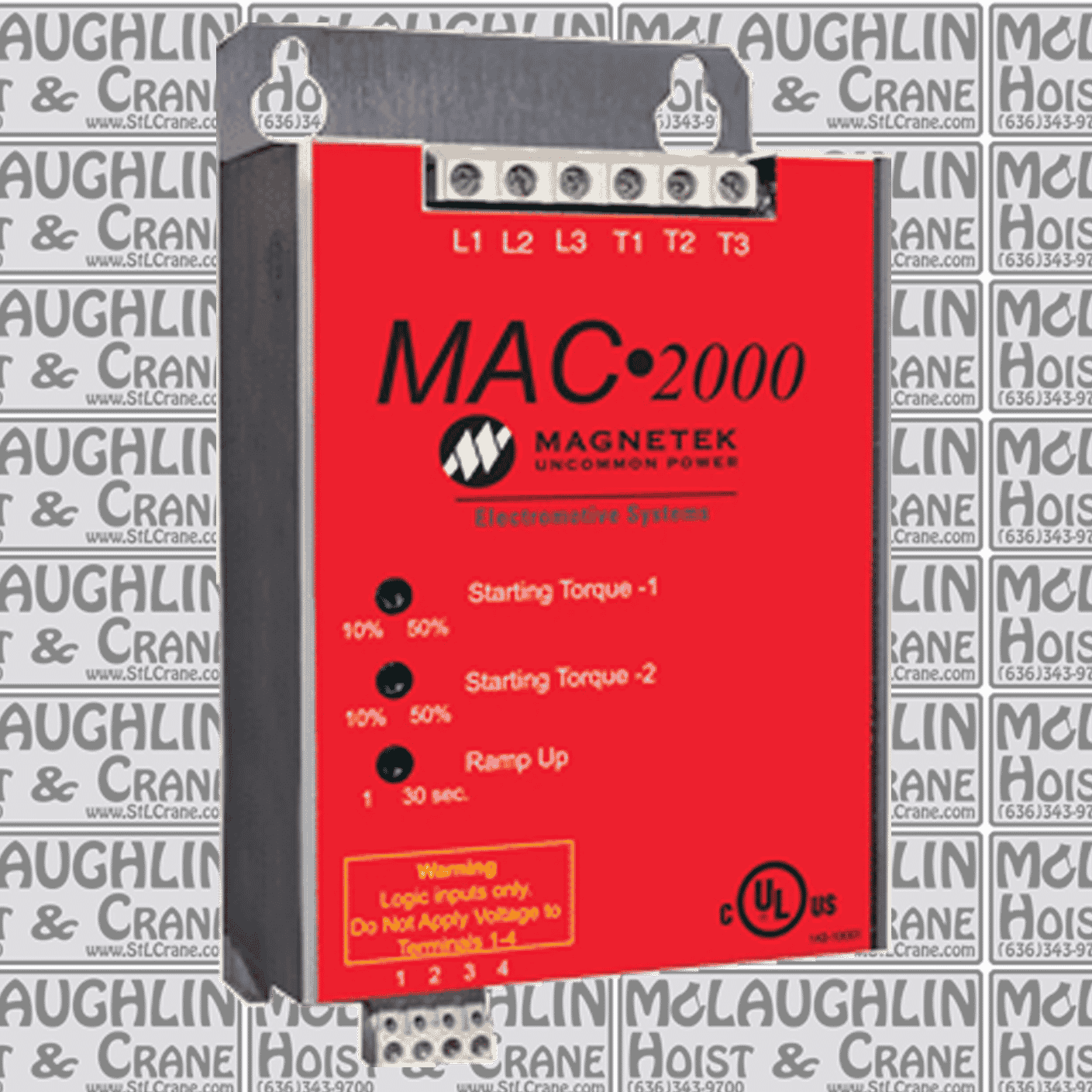

Magnetek MAC 2000 Soft Start

Magnetek MAC 2000 Soft Start

Power Electronics Smooth-Move & Smooth-Move 2

Power Electronics Smooth-Move & Smooth-Move 2

McLAUGHLIN HOIST & CRANE

competitive prices.